Wire cleaners and wire rope greasers are essential in the world of cable repair, in which precision is crucial. These tools are crucial for ensuring smooth cable operation and a long-lasting lifespan in various industries. Wire cleaners and rope lubricators are essential for maintaining cables. In this piece, we discuss their purposes, benefits and the transformative impact on overall effectiveness.

Understanding the lubrication of wire rope

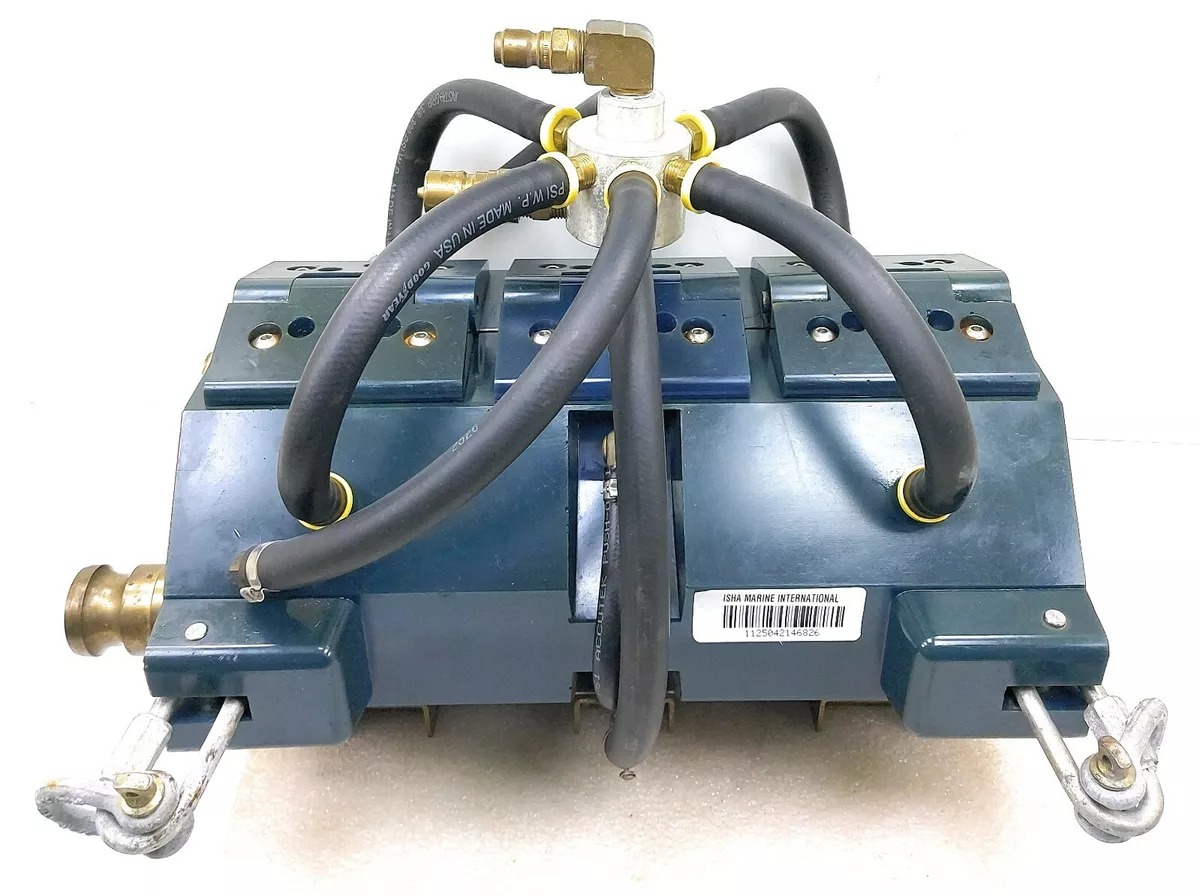

Wire rope lubricators are tools that allow the lubrication process to wire ropes in a systematic manner. This is crucial for preventing rust, reducing friction and improving overall endurance. The lubricator distributes the lubricant evenly across the length and width of the wire rope, to give complete protection against wear.

What is the role of cleaning cables with wires?

Cleaners for wires (also referred to as cable cleaners) are crucial in maintaining the cleanliness and hygiene of cables. These cleaners are designed to clean out fluids, contaminates and dust that get on cables during various operations. In harsh environments the use of cleaners for wire is crucial to ensure the highest performance. Click here Cable Cleaner

Optimizing Cable Lifespan:

Wire cleaners and wire lubricators utilized together can dramatically increase the lifespan of cables. Wire cleaners and lubricators can be used to apply lubrication and eliminate dirt. They also shield cables from corrosion, friction and other external influences. This helps preserve the integrity of the cable, leading into increased efficiency and reduced maintenance costs.

Efficiency in application

Wire rope oilers are created for easy use and effectiveness when used. They are able to be used on many different types and sizes wire ropes, offering versatility when it comes to cable maintenance. Automated and systematic lubrication eliminates the possibility of uneven applications that manual techniques can result in.

The ability to adapt in challenging environments:

In the fields that have cables exposed to extreme environments, such as those employed in drilling, construction or maritime activities, the adaptability of wire rope lubricators and wire cleaners is essential. They are made to endure harsh conditions and provide reliable cable maintenance tools in a variety of conditions.

Cost-Effective Maintenance Solutions for

In the long-term the use of wire cleaners and lubricators for wires to maintain cables is a smart method. The initial investment in these tools is small compared to potential costs such as repairs and replacements caused by improper maintenance.

Conclusion:

Lubricators for wire ropes, as well as cleaners of wires, are the guardians of cable integrity. They ensure accuracy, durability and maximum performance in a variety of industries. Cleansing away contaminants as well as the application of lubricants contributes to the durability and maintenance of cables. This reduces maintenance and improves operational efficiency. The use of cables is still prevalent in the most critical sectors, therefore using tools for maintenance of cables which can help ensure reliability and efficiency is vital.